The Embroidery Production Process: From Design to Finished Masterpiece

Details about machine embroidery production process in garments manufacturing and hand embroidery production process will be revealed by K-Embroidery soon!

1. Hand embroidery vs Machine embroidery

Hand embroidery and machine embroidery are both forms of needlework that involve embellishing fabric with thread. However, there are some key differences between the two techniques.

Hand embroidery is a slow, labor-intensive process that requires the artist to manually insert each stitch. This allows for a high level of creativity and customization, as the artist can choose the type of stitch, the color of thread, and the pattern to create a unique design. Hand embroidered pieces are often considered to be more valuable and heirloom quality than machine embroidered pieces.

Machine embroidery, on the other hand, is a much faster process that uses a machine to insert the stitches. This makes it a good option for large or complex designs, or for people who want to create embroidered pieces quickly. However, machine embroidered pieces tend to have a more commercial look, as the patterns are typically pre-programmed and the stitches are more uniform.

Here is a more detailed comparison of hand embroidery and machine embroidery:

| Hand Embroidery | Machine Embroidery | |

| Process | Slow, labor-intensive | Fast, automated |

| Creativity | High level of customization | Less customization |

| Value | Often considered more valuable | Less valuable |

| Look | More personal, handmade | More commercial |

| Cost | Less expensive | More expensive |

| Skill level | Requires some skill | Easier to learn |

| Materials | Needles, thread, hoops | Needles, thread, hoops, embroidery machine |

| Patterns | Available in a variety of formats | Available as digital files |

| Applications | Suitable for a variety of projects | Suitable for large or complex projects |

In conclusion, hand embroidery and machine embroidery are both beautiful and versatile forms of needlework. The best technique for you will depend on your individual needs and preferences. If you are looking for a creative and personal way to embellish fabric, hand embroidery is a great option. If you are looking for a faster and more affordable way to create embroidered pieces, machine embroidery is a good choice.

In the following sections, I will reveal the embroidery production process in both garment manufacturing and hand embroidery process.

2. Machine Embroidery Production embroidery process in garment industry

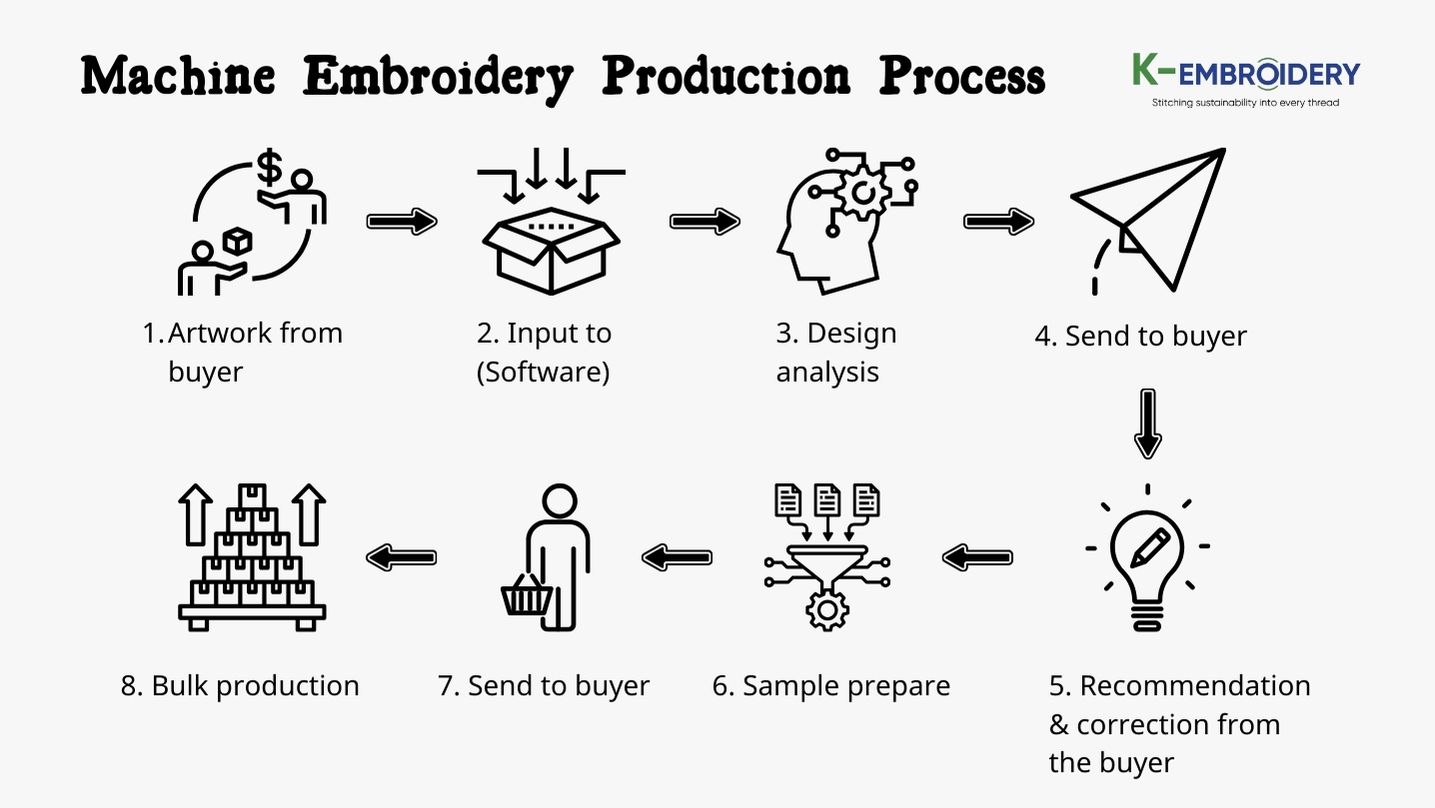

The embroidery process flow chart in garment industry are as follows: Artwork from buyer → Input to (Software) → Design analysis → Send to buyer → Recommendation & correction from the buyer → Sample prepare → Send to buyerIf approved, then for bulk production.

The above flow chart tells the process of embroidery used in garment industry.

- The embroidery production process starts with the digitizer company receiving the artwork from the buyer and fixing it with changes if needed.

- The embroidery supervisor receives the correct tape or disk of embroidery from the production coordinator.

- Then the machine is set up with bulk or 20-48 embroideries to run at one time as per machine capacity.

- The supervisor is responsible for adjusting the machine speed according to the fabric types.

- After the embroidery operation, all the pieces are checked by a needle detector machine and sent into the cutting section.

- Next, the cutting inspector will checks each piece cut.

- The Q.A manager and cutting in charge then check each bundle. Then it proceeds further in the sewing line with an acceptable quantity.

- Before putting it into the sewing line, the quality in charge checked each bundle and passed it to the metal detector machine to ensure the 100% acceptable quantity.

3. Hand Embroidery Production Process

3.1. Choose embroidery pattern

Hand embroidery production process starts with choosing pattern. Because embroidery patterns are very diverse, you need to shape a satisfactory embroidery pattern from the beginning. The choice of embroidery design will affect subsequent factors such as embroidery technique, execution time or selling price of the work.

3.2. Select embroidery materials

In the process of hand embroidery, you need a lot of materials, but among them, two indispensable materials are embroidery fabric and embroidery thread. High-end embroidery fabrics are usually cotton (100%), linen, silk,… while mid-range embroidery fabrics are synthetic fabrics. The choice of fabric will depend on the customer’s order.

Regarding embroidery threads, Vietnamese hand-embroidered threads are often hand-dyed with beautiful materials, different from embroidery threads imported from China. Vietnamese hand embroidery thread is usually silk thread, thin thread, has high gloss, softness, beautiful color, catches light well… these are important factors that contribute to the value of the product.

The most important step in choosing embroidery thread is to choose the right color because in reality, it is very difficult to coordinate colors harmoniously. The embroidery thread color palette requires the chooser to have sensitivity and sophistication in artistic perception. A hand-embroidered work needs many colors of embroidery thread, because the themes are very diverse, not to mention a thread can have different color gradation and shine. Precise, harmonious and flexible embroidery thread color matching requires highly skilled workers and many years of experience. Only by combining beautiful embroidery thread colors can the transition between lines and colors be flexible and natural, creating authenticity and vividness for the final product.

3.3. Proceed with embroidery

After choosing the embroidery pattern and preparing all the materials, the next step is to proceed with the embroidery. Artisans use embroidery techniques from basic to complex and perfect each part of the product. Completion time will depend on many factors such as embroidery size, difficulty of motifs, artisan skills, etc,… but it will certainly not be as fast as machine embroidery. For example, a hand smocked dress pattern at K-Embroidery must be embroidered within 2-3 days.

3.4. Check quality and pack goods

Hand embroidery production process ends with checking quality and packing goods. After embroidery is completed, the work will be checked again, errors will be corrected and excess threads will be removed. If all standards are met, the goods will be packaged and shipped to the warehouse, before reaching the customer.

K-Embroidery has a professional inspection department. The final inspection is 100% done by humans. Each hand embroidered & smocked product is packed in a different zip bag, stored in a sturdy carton before being delivered to customers.

May you also like: Hand Embroidery – Machine Embroidery and The Soul of Products

The above article has shared with readers about embroidery production process. If you have any questions or suggestions about the content, please leave a comment below! K-Embroidery is always welcoming and ready to receive feedback from you!

Contact K-Embroidery manager to buy high quality, cute and safe hand-sewn products for children via WhatsApp: +84855555961 to get the best price and order now!

Contact:

- Address: 5th Floor, Building No. 169 Nguyen Ngoc Vu, Cau Giay District, Hanoi

- Hotline: +84855555961

- Website: https://k-embroidery.com/

- WhatsApp: +84855555961