Summary of 20 International Textile Standards in the Apparel Industry

How can consumers recognize a reputable and quality textile manufacturer? The answer is based on the certifications and standards they achieve.

Below is a summary of the most important and popular textile industry standards today. Let’s find out with K-Embroidery now!

1. What Wholesale Clothing Quality Standards Should a Good Supplier Meet?

Along with socio-economic development, consumers are also becoming increasingly demanding. For the garment industry, which is an essential product, quality standards are even more important. They are the best proof that a manufacturer’s products are meeting consumer expectations and complying with regulations.

Normally, quality standards in the textile industry are divided into the following groups:

- Garment quality standards: Each clothing product must meet quality standards for seams, patterns, colors, finishing and durability. Garment quality standards are especially important for manufacturers of skin-tight clothing (such as underwear) or active sports clothing.

- Fabric quality standards: Fabrics used for costumes must meet quality standards for durability, color fastness, shrinkage, non-irritation,…

- Chemical standards: During the clothing production process, manufacturers do not use toxic substances such as heavy metals, formaldehyde and azo dyes. In general, substances that can endanger human health are prohibited. Chemical standards are of particular interest to manufacturers of children’s clothing.

- Environmental standards: Clothing manufacturers must comply with principles to minimize negative impacts on the environment during the production process. Typically includes standards for waste minimization, water conservation and energy efficiency.

- Social responsibility standards: This is a very popular standard in European countries. Clothing manufacturers should consider social responsibility standards, such as fair labor practices or ethical sourcing of materials.

Which organizations set international textile industry standards for clothing manufacturers?

Some of the most famous and trusted organizations include the International Organization for Standardization (ISO), the American Apparel and Footwear Association (AAFA), and the Sustainable Apparel Alliance (SAC).

2. 20 most important international standards in the textile industry

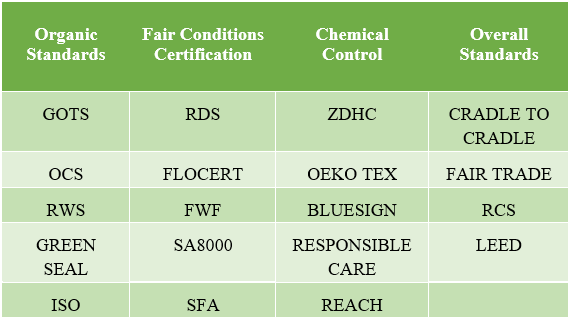

Certificates and Standards in tabular form:

2.1. International Organization for Standardization (ISO) 9001

ISO 9001 certification serves the quality management system, an important component for any organization, large or small, regardless of field, not just the garment industry. ISO certified companies span over 170 countries around the world.

The standard is based on a number of quality management principles including a strong customer focus, senior management motivation and significance, a process approach and continuous improvement. Some textile companies view ISO certification as the only necessary element for export business.

ISO is one of the most trusted standards today. Any organization with ISO certification ensures consistency, good quality products and services, thereby helping to build trust.

2.2. ECO PASSPORT by OEKO-TEX

OEKO-TEX by ECO PASSPORT is an independent testing and certification system for chemicals, colorants and supports used to produce textiles. Oeko-Tex is a registered trademark, representing product labels and corporate certifications issued and other services provided by the International Association for Research and Testing in the Field of Textile Ecology and Leather (also called Oeko-Tex for short).

Oeko-Tex labels and certificates confirm the human ecological safety of textile and leather products from all stages of production (raw materials and fibres, yarns, fabrics, end products ready for use) along the textile value chain. The scope and requirements of Oeko-Tex testing for harmful substances depend on the intended use of a textile product. Oeko-Tex’s Ecological Passport for chemicals is another one of the certificates issued by Oeko-Tex.

2.3. Global Organic Textile Standard (GOTS)

GOTS certification allows organizations to be commercialized worldwide. It is an organic certification issued by a certification organization to ensure industries call themselves “organic” along with the GOTS logo. Any industry with GOTS certification must undergo a thorough review process before bringing products to market, ensuring assurance throughout the supply chain all the way to the consumer. GOTS applies to products including yarn, wool, fabric, clothing and upholstery excluding leather products.

Textile products must have at least 70% contribution from organic agriculture to be called GOTS certified.

What it brings?

- Environmentally friendly production and processing processes

- Better working conditions

- Quality guaranteed by using organic fibers

- Prohibit hazardous inputs such as toxic heavy metals, aromatic solvents, etc.

2.4. Fair Trade Certification

Fair Trade is a certification created by the World Fair Trade Organization to help manufacturers in developing countries achieve sustainable and fair trading relationships. It is applicable to final products that are typically exported from developing countries to developed countries. Therefore, every time a product is launched on the world market, the price is many times higher. Although there are many competitive issues in the market, quality is rarely affected.

In the textile industry, Fair Trade is a highly valued standard. Play a role in ensuring the best working and safety factors throughout the supply process. Thereby helping the company produce products with transparency about ingredients. It also plays a direct role in garment quality. Therefore, each product is guaranteed in quality as well as design.

2.5. Worldwide Responsible Apparel Production (WRAP)

Global Responsible Apparel Manufacturing handles the finances and management of each business. This standard helps businesses operate with high authenticity, safety in design and quality. Above all, the products are committed to maintaining high standards of authenticity. This is a high standard of accountability worldwide.

In addition, coming from a reputable organization, WRAP also has a quite famous name. So this is a really high standard of work. WRAP helps customers understand more about the company. At the same time, from a thorough inspection process, the product is guaranteed. The quality of raw materials used is highly appreciated. Therefore, WRAP is often used as a measure to help customers make the best choice.

2.6. SA8000

The SA8000 standard is one of the world’s leading trusted certifications. It ensures fairness and quality for users. At the same time, maintain quality standards in the textile industry in a fair manner. This standard helps businesses easily control. Thereby creating a comfortable working environment for employees. This standard is a tool to help evaluate the working environment of employees.

At the same time, it is the basis to create the best conditions for workers. This is also a standard that demonstrates the responsibility of businesses towards their employees. Textile industry standards play an important role in every factory. Using it helps employees be fair and have appropriate remuneration. From there, the factory can easily have an objective view of the workforce.

2.7. Bluesign

The term bluesign refers to the responsible use of resources and the lowest possible impact on people and the environment. The certification standard combines aspects of consumer safety, water and emissions, and occupational health with negligible use of hazardous substances.

According to the terms and conditions, manufacturers and brands must act responsibly and sustainably towards people, the environment and resources. Bluesign ensures that the final textile product meets the very strict safety requirements of consumers worldwide and delivers an ideal manufacturing process. Maximum brands use green proven chemicals, which reduces the risk to humanity as well as saves costs.

2.8. Zero Discharge of Hazardous Chemicals (ZDHC)

ZDHC or Zero Discharge of Hazardous Chemicals in the textile, leather and footwear value chain to improve the environment and people’s well-being. It aims to treat harmful substances before releasing them anywhere, thus ensuring safer health conditions.

It includes 3 types of collaborators: Signed Brands, Value Chain Affiliates, and Affiliates. ZDHC is a multi-stakeholder organization comprised of over 170 contributors from across the industry including Brands, Suppliers, Chemical Suppliers and Solution Providers. ZDHC ensures consumer safety by conducting appropriate quality checks at each stage of production.

2.9. Responsible care

Responsible Care is a voluntary initiative of the global chemical industry that aims to bring about changes by improving environmental knowledge, health, safety and security as well as the performance of technologies, processes and products throughout their life cycle to avoid harm to people and the environment.

It analyzes performance openly, which gives it an edge over others. Responsible care monitors progress but also interacts with people to understand and address their concerns and expectations. The voluntary program has been implemented by 62 chemical associations in more than 70 economies globally.

2.10. Restrictions on Chemicals (REACH)

It aims to improve the protection of human health and the environment through earlier and better identification of the intrinsic properties of chemical substances. It aims to strengthen the innovation and competitiveness of the EU chemical industry.

REACH limits the use of toxic substances by replacing toxic chemicals used in industry as well as in everyday life. REACH was established on June 1, 2007. Its main motive is to provide accurate information on chemicals used in industries that may be hazardous to human health.

2.11. Green Seal

Is a global non-profit organization working for a greener, healthier world. It represents a sustainable environment that includes rigorous standards for health, sustainability and product performance. Green Seal was founded in 1989 and since then, Green Seal has pioneered the eco-labeling movement.

Green Seal bases its standards development processes on internationally recognized best practices, as described in the ISEAL Code of Standards Setting (2014). This code allows the entire production process to be transparent.

2.12. Leadership in Energy and Environmental Design (LEED)

LEED is the most used green building rating system in the world. LEED creates buildings that are cost-effective, energy-efficient, and environmentally friendly. It is present in 165 countries and territories.

A LEED certified company is recognized worldwide for green building. These buildings save energy, water, resources, create less waste and support human health.

2.13. Organic content standards (OCS)

OCS certification allows the use of organic materials throughout the processing phase. It verifies the presence and amount of organic materials in the final product. OCS 100 is at least 95% certified organic fiber. Products include yarn, wool, fabric, clothing and upholstery excluding OCS leather products.

Control Union is the leading certification organization, having certified the majority of all certified facilities. OCS enables transparent, consistent and comprehensive independent assessment and verification of organic material content claims on products.

2.14. Fair Wear Foundation (FWF)

FWF works for safer working conditions, reducing any risk of injury, thereby bringing about sustainable improvements to workplace conditions. Brands should check whether their manufacturer is FWF certified if they prioritize having safe working conditions where their products are manufactured.

2.15. FLOCERT

Is a global certification and verification agency for Fair Trade products. It enables companies to follow ethical business standards and fairness in their supply chains. Having FLOCERT certification increases an organization’s recognition in the global market.

2.16. Responsible Wool Standard (RWS)

The Responsible Wool Standard (RWS) provides the opportunity for farmers to grow the best quality wool according to global standards. RWS focuses on treating sheep properly and maintaining the quality of the land they graze on.

The benefit of having RWS certification is that it helps verify the activities taking place at farm level, giving brands a clear solution that allows them to make claims about their wool sourcing.

2.17. Responsible Standards (RDS)

Exploitation is common in the textile industry where animal resources are used. To eliminate this, RDS ensures animal welfare in down and feather products. In particular, animal products such as feathers and down, wool, angora, cashmere and leather are tested to ensure their safety.

The RDS was developed by Control Union, The North Face and Textile Exchange through an extensive stakeholder review process, which involved downstream supply chain members around the world and international organizations major animal welfare organization.

2.18. Recycling Requirements Standard (RCS 100)

RCS (Recycling Requirements Standard) is used as a chain of custody standard to track recycled raw materials through the supply chain. To ensure minimal loss during processing steps, raw materials are recycled as required. RCS checks the presence and amount of recycled materials in the final product.

2.19. Sustainable Fiber Alliance (SFA)

SFA’s Sustainable Cashmere Standard was established to address sustainability challenges in cashmere production. It serves the safety and welfare of goats and herders. It was developed in 2015 as the world’s first comprehensive sustainable cashmere standard. The SFA standard is based on the Textile Exchange Content Requirements Standard, a standard that supports many other sustainability certifications and has therefore been adopted by industry.

2.20. Cradle to Cradle Certification (C2C)

It is a multi-attribute label that provides a means to demonstrate efforts in eco-smart product design. It focuses on areas such as eco-friendly materials, recyclable materials, water and energy efficiency, etc. It is applied to raw materials to finished products.

3. The importance of international standards in textile industry for clothing manufacturers

In the context of so many new garment companies springing up every year, determining which is a reputable company is not easy. And textile certification standards are a yardstick that helps evaluate the quality of manufacturers.

Benefits of meeting textile industry standards:

- Build customer trust in the manufacturer’s products.

- Help protect the environment and build sustainable fashion trends

- Ensuring safe quality of input materials

- Controls the amount of chemicals in fabric, protects skin and is not toxic to humans.

4. Key quality control measures in the textile industry

Effective quality management starts with building structured, repeatable systems. In the fashion industry quality checks must be embedded at multiple stages—from design to final packaging. Early-stage quality planning is essential for preventing defects later in the production process and ensures that garments meet both aesthetic and functional standards. By addressing quality from the outset, businesses can guarantee that their products are not only visually appealing but also durable, comfortable, and capable of meeting consumer expectations. This proactive approach reduces the risk of costly returns, enhances customer satisfaction, and reinforces the brand’s reputation for excellence.

4.1. Fabric and Material Inspection: Ensuring Durability and Comfort

The foundation of any garment is its fabric. One of the first steps in garment inspection processes is verifying fabric quality upon arrival from suppliers. This process includes testing for factors such as shrinkage, pilling, texture consistency, and fiber strength. Even high-end designs can falter in the market if the fabric fails to deliver the expected comfort or durability. Wholesalers who prioritize material testing early in the production process are better positioned to deliver products that not only meet but exceed customer expectations, leading to fewer returns and complaints in the future. By ensuring the fabric’s quality from the start, businesses can enhance product longevity and maintain a strong reputation in the market.

4.2. Stitching and Construction: The Foundation of Garment Quality

The next crucial checkpoint in ensuring product quality is garment construction. Even the highest-quality fabric can be rendered unwearable if the stitching is subpar. Seam strength, proper alignment, and meticulous finishes are essential components that significantly impact the garment’s perceived value. A reliable quality control team must examine not only the visible seams but also the internal stitching, reinforcements, and trims to ensure every garment meets the highest standards. By focusing on these details, businesses can prevent defects that affect both the functionality and overall appeal of the product, ensuring long-lasting customer satisfaction. In the context of quality management in wholesale, this step is essential for reducing returns and ensuring long-term retailer satisfaction.

4.3. Sizing and Fit Consistency Across Bulk Orders

Inconsistent sizing is one of the primary causes of returns and customer dissatisfaction in wholesale fashion. To mitigate this, manufacturers must implement a standardized size grading system and conduct regular fit tests across all production batches. This becomes even more critical when selling internationally, as sizing standards can vary significantly between regions. By ensuring accurate and consistent sizing, businesses can reduce return rates, improve customer satisfaction, and foster greater trust in their brand across global markets.

Maintaining consistent fit not only improves customer satisfaction but also plays a major role in reducing defects in fashion products. It minimizes costly errors, prevents excess stock, and helps retailers protect their reputation.

4.4. Color and Print Accuracy: Maintaining Brand Integrity

Accurate color and print reproduction is essential in maintaining brand trust, especially in wholesale clothing in Turkey, where buyers often rely on photos or digital catalogs to make decisions. Even minor discrepancies in shade or pattern can result in returns, customer complaints, and potentially harm business relationships.

To prevent such issues, wholesalers should implement rigorous quality control measures, standardize color profiles across production teams, and assess fabric samples under various lighting conditions. Ensuring precision in these details safeguards brand integrity and fosters long-term trust and confidence from buyers.

5. K-Embroidery – Children’s clothing manufacturer with STANDARD 100 by OEKO-TEX® label

K–Embroidery is a highly experienced and professional manufacturer of hand-smoked and embroidered children’s clothing with over 25 years of expertise. Based in No.169, Nguyen Ngoc Vu Street, Cau Giay district, Ha Noi, Viet Nam, our specialization is creating high-end boutique-quality clothing exclusively designed for babies and exporting all over the world. Find more About Us !

At K-Embroidery, we respect current textile standards. As a top manufacturer in Vietnam, K- Embroidery tries its best to make “green” fashion, providing high-quality and at the same time, eco-friendly garments. Continuous efforts have helped K-Embroidery achieve STANDARD 100 by OEKO-TEX® label in 2016. This means you can have complete peace of mind when using products from the K-Embroidery brand.

One of the product lines not to be missed at K-Embroidery is the Hand Smocked Children Clothing product line. 100% processed by Vietnamese workers, high quality fabric (cotton, silk, linen) absolutely safe for children,… You can immediately refer to our collection here!

Above is Summary of 20 international standards in textile industry. Hope this information will be useful. See you in the next articles!

Contact K-Embroidery manager to buy high quality, cute and safe hand-sewn products for children via WhatsApp: +84855555961 to get the best price and order now!

Contact:

- Address: 5th Floor, Building No. 169 Nguyen Ngoc Vu, Cau Giay District, Hanoi

- Hotline: +84855555961

- Website: https://k-embroidery.com/

- WhatsApp: +84855555961